As I have an invested interest in consistent electricity back home (see my other recent post on Solar for details) and have been in discussion with the council about net metering and grid tie, I’ve been doing quite a bit of random reading regarding electricity distribution and its various facets.

Not many of us know that the power company / municipality also uses in-line signalling (aka ripple control) to implement power control and load shedding, so I thought I’d do a little writeup on that.

Many of us have noticed that streetlights don’t always come on, or go off when its light or dark – they appear to be on a timer system.

What most people don’t know is that the timer system controls are actually implemented centrally at substations, and these add signals to the power lines to tell the equipment to turn off / on when instructed.

This is done using ripple control codes.

With ripple control, a small signal is added to the incoming A/C at a distribution location – eg a substation. This signal is read by a special relay in place on the larger circuits (typically the Geyser), and turns power off or on when the electricity company requires – usually when power is scarce, and they need to shed some load.

As this signalling can work on multiple channels, each listening relay can be set to listen to a specific channel, and used to power specific things on / off remotely (e.g. Streetlights).

In South Africa, we use DECABIT signalling to tell things to turn off and on, as well as the older K22 signalling standard.

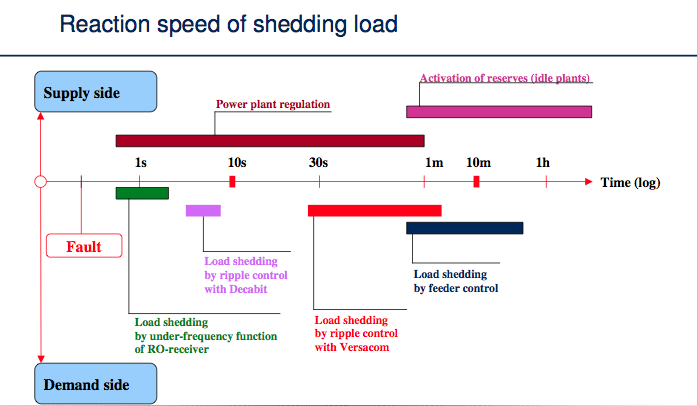

When load shedding needs to occur, the electricity distribution system needs to act fast to avoid system failures. Most things are automated, and happen in order of timing.

Implementations of the protection mechanisms in place have a specific time to occur – eg a latency. Responses to conditions also have a latency – eg getting additional idle power plants online to provide more power when needed, so its important to the grid to have multiple control and response mechanisms to respond to loads. Each response mechanism also has a different cost impact, so its also important to the electricity provider to best manage these.

A diagram of this is below (Excerpted from http://www.anime-za.net/tech/literature/Enermet_Farad.pdf ):

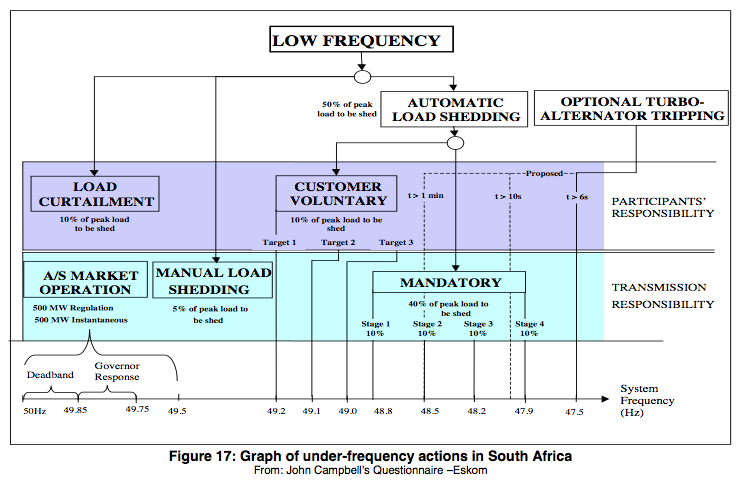

For light variances in load, frequency changes as generators speed up or slow down to supply enough electricity to the supply. If there isn’t enough supply to meet load, then frequency drops, and large scale equipment will disconnect until load decreases. This happens almost instantaneously – responses to these issues resolve with a latency of within a few milliseconds to a second. This is called Under-Frequency Load Shedding (UFLS).

As seen in the diagram above Eskom implements automated under frequency load shedding in an increasing percentage margin based off frequency rates.

(Additional details are in the PDF below)

The next set of load shedding is the one we’re interested in – ripple signalling. If the system still has too much load after 1 second, then it sends out a signal over DECABIT to turn off more equipment. DECABIT signalling has a latency of about 7 seconds – a minimum DECABIT signal frame is 6.6 seconds, so this is a second stage response to issues.

As each substation can be connected to up to 20,000 homes/customers (depending on substation load capacity), this allows localized load shedding where its needed, when its needed.

Eskom calls this Demand Market Participation, and has roughly 800MW of systems added into this mechanism. Municipalities are particularly keen on putting loads onto these mechanisms via DECABIT compliant relays, as this saves them peak power fee’s when loads are high – if they can temporarily cut off power to consumers for 10 seconds – 10 minutes for non-essential high loads, then they can substantially reduce what power costs them from Eskom, and make additional profits.

A good writeup on Demand Market Participation is below:

Eskom benefits as they can temporarily avoid adding more infrastructure to cope with growth.

This has been the case for a few years now, but it only delays the inevitable – you do need to invest in infrastructure, not incentivize clients to use less.

Eskom also has a secondary mechanism (using the same theory – lets encourage you to turn off power) called VPS. They have an additional 50,000MW of connections using this on a contractual basis – typically industrial users., and are looking to increase this number.

Its only been through introduction of these mechanisms that we’ve been able to stave off grid collapse. Its gotten so bad, that industrial users have been looking closely at what they can do to provide their own power when Eskom can’t.

Other countries – notably Germany, and the UK, have allowed consumers to become producers, by encouraging localized small scale production of electricity, thus helping the grid without requiring additional investment from the incumbents. This is called net metering – where both inputs and outputs are metered.

Eg – if you have a solar system that provides excess power during the day, it can feed into the grid – (when it needs it most), and they’ll credit you for your participation.

So far, South Africa has been rather reticent to implement this, as the short sighted vision is that its “stealing” from the incumbents profits.

A choice excerpt from that PDF is this –

Residential load can also be incorporated within the VPS, particularly when integrated with Smart Metering systems. Numerous pilot and small scale projects are being undertaken within both Municipalities and Eskom in response to the DOE’s Regulation 773 of 18 July 2008.

The Department of Energies regulation can be found here –

http://www.energy.gov.za/files/policies/Electricity%20Regulations%20on%20Compulsory%20Norms%20and%20standards%20for%20reticulation%20services%2018Jul2008.pdf

These state that all systems over a certain size require that smart metering be installed by 2012. As you may have guessed, quite a few municipalities have not met this deadline, and Eskom has been dragging its feet on that too.

Ironically, introduction of smart metering would actually help the grid here in South Africa, as IPP’s (independant power producers) would make the grid more stable by providing additional energy when needed, and at a lower cost than the incumbents can create it for.

This however does have its issues – most municipalities generate revenues from Electricity, and so are loath to change the status quo, even when it would benefit the country from a whole.

So, its unlikely to be implemented in the short-medium term, unless the government drags them kicking and screaming through the process.

In summation, this –

Lawrence.

———

References:

http://en.wikipedia.org/wiki/Zellweger_off-peak

http://www.anime-za.net/tech/ripple_index.html

http://mybroadband.co.za/vb/showthread.php/134334-And-so-I-have-proved-the-ripple-control-system-is-buggered

DECABIT Ripple Signal Guide

Thesis on the financial implications of relaxing frequency control as a mechanism.

http://www.energy.gov.za/files/policies/Electricity%20Regulations%20on%20Compulsory%20Norms%20and%20standards%20for%20reticulation%20services%2018Jul2008.pdf – DoE Regulations

http://www.enerweb.co.za/brochures/AMEU%20Conference%20-%20Enerweb%20VPS%20Paper%20-%20201109%20-%20%20V1.0.pdf – Demand Market Participation

http://www.systemoperator.co.nz/f3210,36010947/Appendix_A_-_A_Collation_of_International_Policies_for_Under_Frequency_Load_Shedding.pdf – Load Shedding in International operators

13

Going Solar

I’ve been interested in going completely solar for a while now back home in South Africa, as pricing for electricity has rapidly increased past the pricing for solar; return on investment is in the 3 year range currently.

It will get close to 1 1/2 year return on investment when Eskom new pricing increases happen, so its a no brainer to install.

I’ve already replaced our geyser (hot water system) with a solar based system, plus all the lighting in the house is already LED based (yay China!), so our base load of electricity is low for the size of the house. I can still improve though by installing solar, to make the electrical costs approach zero, and at some indeterminate point in the future when Eskom allows for legalized grid tie, a profit center!

As I’ll nominally be a 10KW producer (I can add 2 panels to get there), I should be able to at some point pump back into the grid sooner rather than later – as the trial projects for Cape Town all sit at the 10KW range and up…

From what I read –

Eskom will pay out R 1.20 per kilowatt hour

generated by your solar system for the first three years, 70% immediately after installation

and the balance at 10% for the next three years.

More here – http://www.capetown.gov.za/en/EnergyForum/Documents/Eskom%20IDM%20small-scale%20renew%20energy%20-%20Lodine%20Redelinghuys_31Aug2012.pdf

(Yes, currently this is only available for commercial use, but I do expect that to change at some point. My system should be in use for at least 25 years, so I should get some benefit at some point in the future.)

—-

Before I get to pricing though, I need to explain how it all works.

For any system, you’ll need some kind of input.

As I’m looking at Solar, thats my input. I can also look at thermal or wind based. Wind based is a distinct possibility in Cape Town, but I have been advised that its probably too windy to use! (turbines can’t run during extremely windy weather or you break the turbines).

So, I’m going with Solar.

There are 2 types of solar panel out there. Monocrystalline and Polycrystalline.

Monocrystalline is more expensive per watt, as its a more difficult process to make panels from.

Mono panels are also slightly smaller per watt of output. On average mono panels are about 14% smaller. They also work better in hot climates.

Aside from those differences, they’re fairly similar.

Panels are typically rated in watt terms.

A 300w panel will give you 300W of power at peak output (eg mid-day).

This 300w of power is at DC voltage though, and for house use, we need A/C

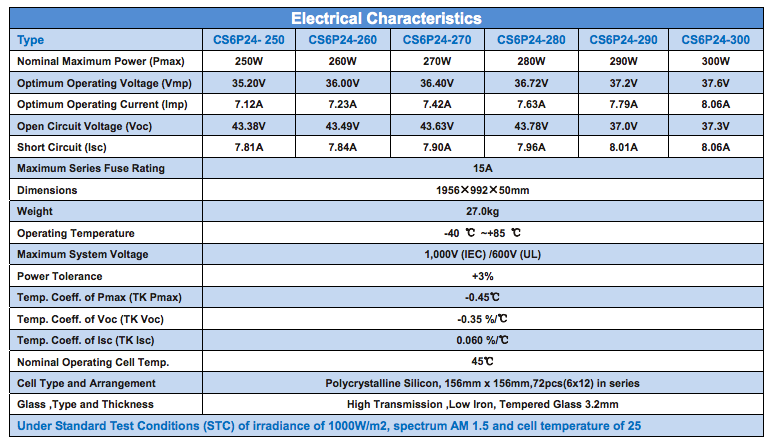

The 300w panels I’ve been looking at give 36V @ 8.3A.

I’ll probably go with polycrystalline, as the pricing isn’t really worth the extra 30% for mono crystalline for my needs.

Panel info below – (click me for pdf)

Basic calculation for power output is P = V * A

This works out to 300W a panel (303W = 37.6V * 8.06A)

I’ll be getting 30 panels, as thats about the max I can fit on my roof in theory.

(My brother hasn’t gotten me the exact sizing yet).

To use this, we need an inverter though, as something has to convert the DC power into AC.

In my house, I have 3 phase power, and an antique metering system.

3 Phase is good, as i have sufficient power for my needs, but its bad as I need a more advanced inverter to give me 3 phase.

I could use 3 x single phase inverters, but for simplicity, I’ll be going with a single 3 phase inverter.

If you see the cabling here – you’ll see we have 3 phases + 1 neutral = 4 cables.

To work out what sort of inverter I can use, I need to do some basic math.

I’ll have 30 Panels total.

Each panel gives out 36V @ 8A., and that will give me approximately 9KW output. As the smallest *decent* 3 phase inverters I could find are 10KW ones, thats a good size.

I have a choice of running the panels in series or in parallel.

If I run them in series, then the Voltage increases.

Eg 1 panel = 37v, 2 panels = 74v @ 8A…

If I run them in parallel, then the Ampage increases.

Eg 1 panel = 8A, 2 panels = 16A @ 37v

If you’ve ever seen welding cables or car battery cables, you’ll see what sort of cabling is required for high Amps. So, everyone wires using DC voltage.

My inverter of choice is probably going to be this: Growatt10000UE

That 3 phase inverter has the following characteristics.

It will power up from 300V (min voltage to run), and accepts voltage up to 1000V.

It also has 4 inputs for panels.

Generally each input is called a “string”.

As I’ll have 30 panels, I’ll probably be balancing them out in 2 x 15 piece strings -> the inverter.

Each string will work like this

37V * 15 = 564V DC * 8A (4.54KW of power)

37V * 15 = 564V DC * 8A (4.54KW of power)

This will give me a rough total of 9W peak power.

As conversions are never perfect, and panels can output more during peak than they are rated for, I’m getting a 10KW inverter. This will allow for some small headroom in future if I need to expand slightly.

It also is fine for something I haven’t talked about yet – open circuit. The panels I’m looking at run at 36v open circuit (i.e. before they kick in), the inverter also needs to be able to work without issue at open circuit voltages. As the inverter supports 1000v, open circuit of 564v isn’t an issue.

So far, costs are:

30 Panels = 720RMB / poly panel = 21,600 (mono panels are about 900-1000 per piece). Poly panels are physically 1.9M x 1M @ 300w / 28KG , Mono 1.9M x 1M @ 300W / 25kg

10KW 3 Phase inverter = 9,000RMB

Weight = 1000KG with packing.

Shipping + clearance – roughly 15,000 + duties @ 20%

Total landed in Cape Town = 45,000RMB / R60,000

That gives me a rough pricing of R6.6 a watt *installed*.

It also gives me a system that I can hook into the grid (illegally currently!), but won’t provide for power in case of failure.

I actually don’t need something that size, but sadly, due to the cost of clearance being a complete rip off, it doesn’t make sense to ship less 🙁

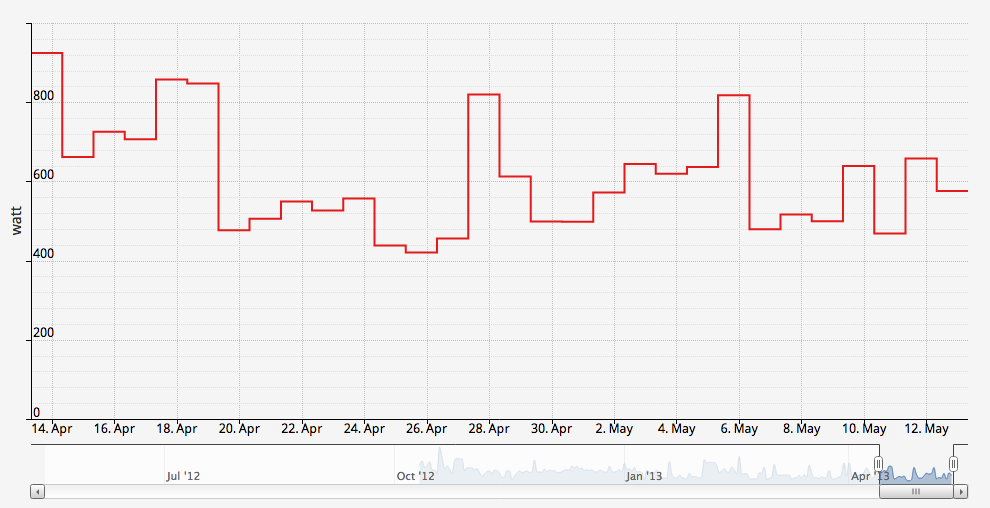

Currently our power bill sits at about 700-1000 rand a month, over a year this is around R12,000 using worst case scenario maths 😉

My intended system will cost me about R60,000 + install labour. At current electricity pricing, I should see a complete payback for the system in about 5 years. Given that electricity prices are going to be *doubling* over the next 5 years in Cape Town, this will actually be achieved in about 3 years or so.

Not too shabby!

Our current monthly electricity usage looks like this for those who may be interested.

You’ll note that electricity use spikes on certain days (mainly weekends) – this generally ties into when the maid is there, as then the washing machine, dish washer etc get run, or on the rare occasion that my brother actually cooks 😉

Initially I’ll be feeding excess power back into the grid, and using that as a “battery”.

How will that work?

Well, as I have an older meter, it can run backwards. So, daytime when I have _substantial_ excess, i’ll be running backwards, and nighttime, when the solar panels are not generating, I’ll be running forwards.

Essentially, using the grid as my battery..

Eskom will be benefiting from all this, as I’ll be a net producer far over what I consume – so they’ll get all the free electricity I’ll be generating.

Its also safe – as the inverter will not feed back into the grid if its offline – eg when we have one of our rather too regular power outages (3 in the last month from my logs).

Longer term I’ll be installing a battery system to allow for complete off grid, but funds don’t currently stretch to that yet..

Do note that the above is for my needs – your needs might not be my needs!

I need a 3 phase system. Most people _don’t_. I’m also going grid tied for the moment due to funding available. Others might find it better to have a hybrid grid tie/ battery system. If I could afford it, I’d go that route!

I’m also *heavily* overspeccing the output – clearance costs are substantial for South Africa (highest in the world almost), so it doesn’t make sense for me to ship a small system, as there is only a marginal cost for what I’m speccing.

A suitably sized system for us would be 8 panels, and a 3kw inverter. I’d be crazy to ship that though, as the clearance is more than the cost of the system. So, I’m heavily overspeccing on requirements so that it makes sense. Long term its also a no-brainer for me, as I’ll have substantial excess I can sell back to the grid.

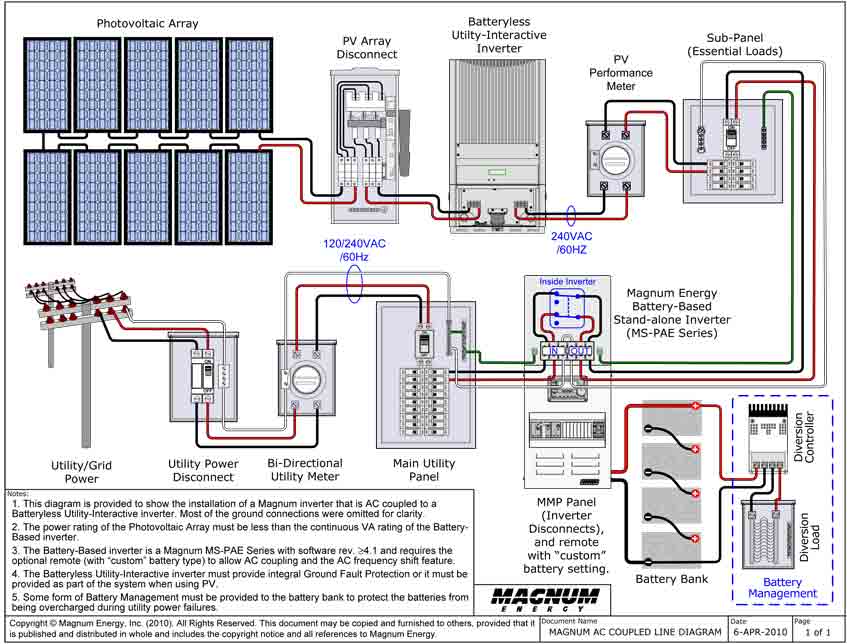

In case anyone is interested how I’ll retrofit this sort of system with a battery backup – here is a diagram of a single phase implementation – I’d be doing something similar:

That said, I do have another easier solution – I’ll probably go cheap – stick the things that may not lose power(tm) circuit on a 2KV UPS, and have an isolator switch in circuit for when the grid goes down so its isolated from Eskom. This will accomplish the same thing pretty much, and should tide us over for the average 3-4hour outages we seem to experience every few weeks. It will also sit nicely in the computer rack that will contain the media side of the house and data storage needs 🙂

25

How to make biltong

As there doesn’t seem to be any Biltong available in China, I’m creating my own here in South Africa, so I can bring back for friends.

This makes about about 3-3.5kg of biltong once dry.

Our model for the day – my cousin Joel.

Instructions below:

Creating our Biltong Drying Box

First, go buy a plastic storage box, this needs to be fairly deep, as we will be hanging meat vertically. Recommend buy something with an easily removable lid thats transparent for easier checking on biltong production.

We procured our box at Plastics Warehouse opposite Kenilworth Centre in Cape Town. Carrefour in Shanghai has suitable boxes for those in China.

We prepared the box for usage, by drilling lots of small airholes in the side, and lid, swiss cheese style. Recommend use a drill with a 1mm bit or similar. The idea is that air can go in, but nothing else.

Once the airholes have been created, we drilled holes for dowels that the meat is going to hang on.

Dowels should be near the top of the box, and spaced appropriately. Note that the meat cannot touch the sides of the box, so make sure to leave enough space on the left/right of the dowels for the thickest cuts of meat. Our efforts are below:

Biltong Box

Archives

- November 2024

- November 2019

- October 2019

- August 2019

- April 2019

- February 2017

- September 2016

- June 2016

- May 2016

- September 2015

- August 2015

- June 2015

- April 2015

- December 2014

- October 2014

- September 2014

- July 2014

- June 2014

- April 2014

- October 2013

- July 2013

- May 2013

- April 2013

- March 2013

- January 2013

- December 2012

- October 2012

- August 2012

- July 2012

- June 2012

- May 2012

- April 2012

- March 2012

- December 2011

- November 2011

- October 2011

- September 2011

- July 2011

- May 2011

- April 2011

- March 2011

- February 2011

- January 2011

- December 2010

- November 2010

- October 2010

- September 2010

- August 2010

- July 2010

- June 2010

- May 2010

- April 2010

- March 2010

- February 2010

- January 2010

- December 2009

- November 2009

- October 2009

- May 2009

- April 2009

- March 2009

- February 2009

- January 2009

- December 2008

- November 2008

- October 2008

- September 2008

Categories

- Apple

- Arcade Machines

- Badges

- BMW

- China Related

- Cool Hunting

- Exploits

- Firmware

- Food

- General Talk

- government

- IP Cam

- iPhone

- Lasers

- legislation

- MODx

- MySQL

- notice

- qmail

- requirements

- Reviews

- Service Issues

- Tao Bao

- Technical Mumbo Jumbo

- Things that will get me censored

- Travel

- Uncategorized

- Useful Info